PRODUCTS

PVC Plastic Recycling Pelletizer

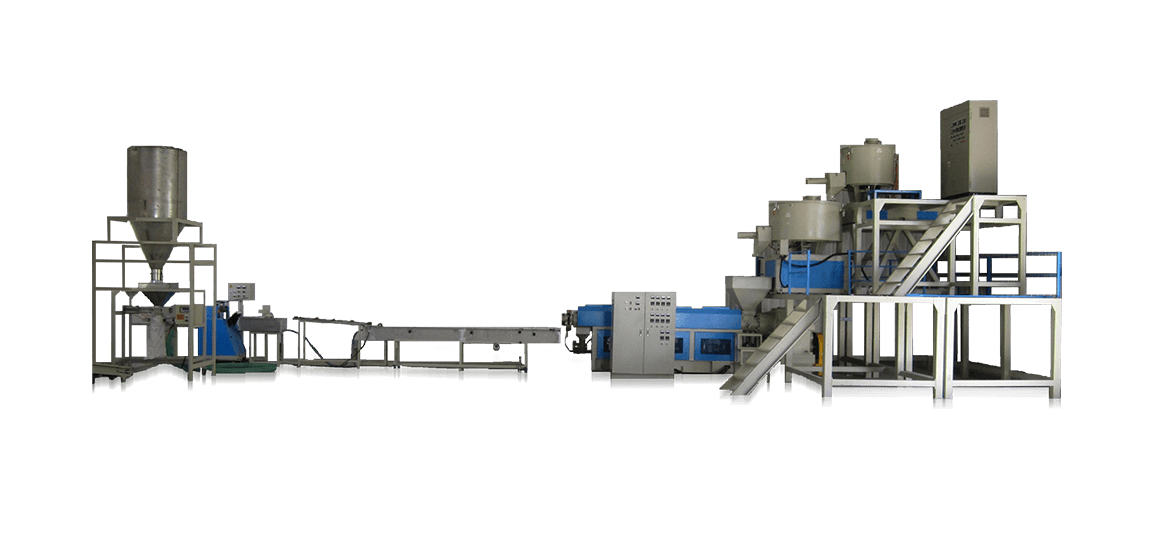

PVC Plastic Recycling Pelletizer

Features

The PVC Plastic Recycling Pelletizing Machine is a specialized set of equipment designed for processing and recycling industrial and agricultural waste plastics. This machine efficiently converts PVC waste into high-quality, reusable pellets, suitable for manufacturing various plastic products.

How the PVC Plastic Recycling Pelletizing Machine Works

The PVC plastic recycling pelletizing process begins with mixing PVC waste in a mixer. The ratio of PVC waste varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into a single-screw or twin-screw extruder. The extruder screws rotate, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded pellets. The extruded pellets are then cooled and set through a cooling device. The haul-off machine pulls the pellets through the cooling device, maintaining their shape and ensuring correct dimensions. Finally, the cutting machine cuts the pellets to the desired length, and the stacker stacks the finished product.

- The plastic pelletizer is able to extrusion plastic raw material, including PVC compounds, rigid PVC, rigid waste recycle, and soft PVC from DOP 40% to 100%.

Specifications

| MODEL | CY-100P | CY-120P | CY-150P |

|---|---|---|---|

| EXTRUDING CAPACITY(KGS/HR) | 90 ~ 160 | 150 ~ 250 | 300 ~ 400 |

| SCREW DIAMETER (MM) | 100 m/m ø | 120 m/m ø | 150 m/m ø |